Product Category

Hot Products

Contact Us

- Add: No. 6 Yangpu Rd., Hai'an, Jiangsu, China

- Contact: Ms. River Chu

- Moble: 0086-13862710999

- Fax: 0086-513-88361005

- Web: www.jsblks.com

- Email: riverchu@gmail.com

Proudct Detail

Product Name:

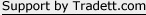

Six-High Levelling

Model: QR-QWG43-6x2000

Categories: Six-High Levelling

Performance features for Six-high levelling machine:

◆ The machine employs a frame structure and has characteristics of high strength and good stiffness.

◆ It has high surface protection for processing materials and high leveling accuracy.

◆ Every single surface has three layers of rolls: support roll, intermediate roll and work roll.

◆ It employs a six-high leveling structure of a leveling roll, a complete support roll and multi-group support rolls.

◆ Levelling rolls and support rolls material: GCr15, 9CrS and 9Cr2Mo are available for selection.

◆ Levelling rolls and support rolls final process: refining, hard chrome plating, fine polishing; gap clearing device is designed for adjustment and depressing.

◆ Reducer: TR reducer and ZLY reducer with hard tooth surface is available for selection.

◆ Universal connecting shaft: made of alloy structural steel.

◆ Technology for heating processing, distribution box structure, adjustment and lubrication methods are the same as those for four-high levelling machine.

Description:

◆ It has high surface protection for processing materials and high leveling accuracy.

◆ Every single surface has three layers of rolls: support roll, intermediate roll and work roll.

◆ It employs a six-high leveling structure of a leveling roll, a complete support roll and multi-group support rolls.

◆ Levelling rolls and support rolls material: GCr15, 9CrS and 9Cr2Mo are available for selection.

◆ Levelling rolls and support rolls final process: refining, hard chrome plating, fine polishing; gap clearing device is designed for adjustment and depressing.

◆ Reducer: TR reducer and ZLY reducer with hard tooth surface is available for selection.

◆ Universal connecting shaft: made of alloy structural steel.

◆ Technology for heating processing, distribution box structure, adjustment and lubrication methods are the same as those for four-high levelling machine.

| ; Specification | Max. thickness | Min. thickness | Max. width | Board yield limit | Distance between working rolls | Working roll diameter | Roll qtt. | Working speed | Main motor power | Overall dimensions |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (m/min) | (Kw) | (LxWxH)(m) | |

| QWG43-2×800 | 2 | 0.6 | 800 | 360 | 50 | 48 | 21 | 6 | 7.5 | 3.59×1.58×1.4 |

| QWG43-2×1300 | 2 | 0.6 | 1300 | 240 | 55 | 50 | 19 | 10-60 | 55 | 5×1.26×1.8 |

| QWG43-3×1600 | 3 | 0.8 | 1600 | 240 | 70 | 65 | 15 | 10-30 | 45 | 3.59×1.58×1.4 |

| QWG43-3×2500 | 3 | 0.8 | 2500 | 300 | 80 | 75 | 19 | 10 | 37 | 7.2×3.27×1.74 |

| QWG43-6×2000 | 6 | 1.5 | 2000 | 360 | 100 | 95 | 13 | 8.6 | 45 | 6.62×3.53×1.7 |

Previous Product:none

Next Product:none